In September this year, EMO 2025, one of the world’s largest machine tool trade shows, was held in Hanover, Germany.

As a third-year employee, this was my first overseas business trip, and I had the opportunity to participate in the exhibition.

The inspection team consisted of three members: our president, the design section chief, and myself from the development team.

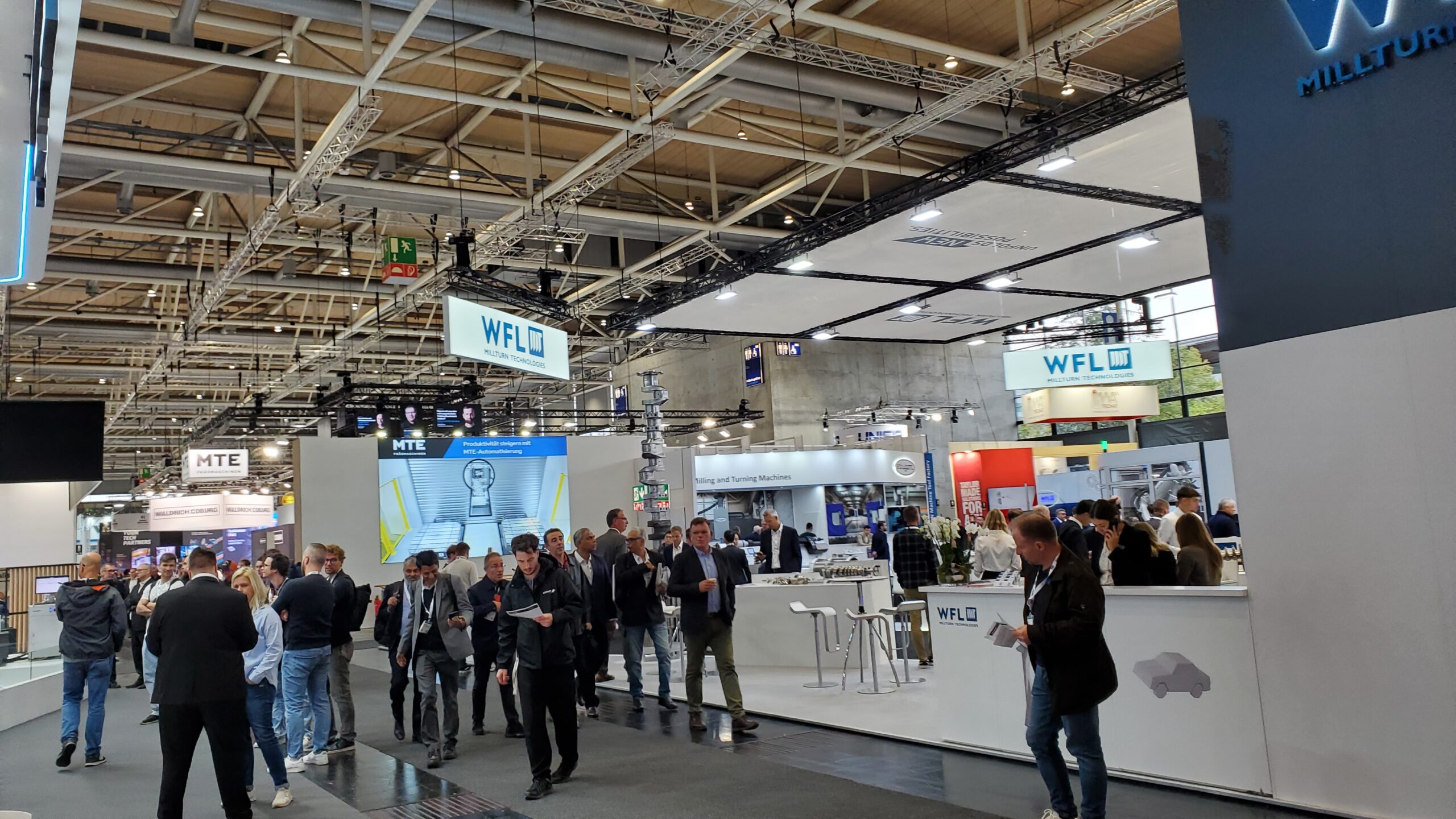

EMO 2025 is an international event where machine tool manufacturers and related companies from around the world gather to showcase the latest technologies and products.

Since I had only had very few opportunities to see other companies’ equipment or observe overseas manufacturers firsthand before, this experience was both fresh and highly inspiring for me.

Impressions from Visiting Overseas Manufacturers’ Booths and Products

The moment I stepped into the venue, I was overwhelmed by its vast scale and the lively atmosphere.

Each company’s booth was full of personality, and I could feel a strong commitment not only to their products but also to how they presented them and the concepts behind them.

What impressed me the most was the commitment of European manufacturers to automation and digitalization.

Some booths had machines running live, creating a very immersive experience.

There were also demonstrations of various software and management systems, showing technologies I don’t usually see firsthand.

Seeing these technologies in action made them feel much more real to me.

For peripheral equipment manufacturers like our company, understanding the overall trends in manufacturing sites and exposure to overseas ideas is extremely important for considering our own position and direction.

The staff at the booths were also very friendly and answered our questions politely.

Although I’m still not very confident in English, I did my best to choose my words and was able to communicate directly. 👍

Hearing about product features and development goals from the people on-site gave me insights that can’t be found in catalogs or brochures, making it a very valuable experience.

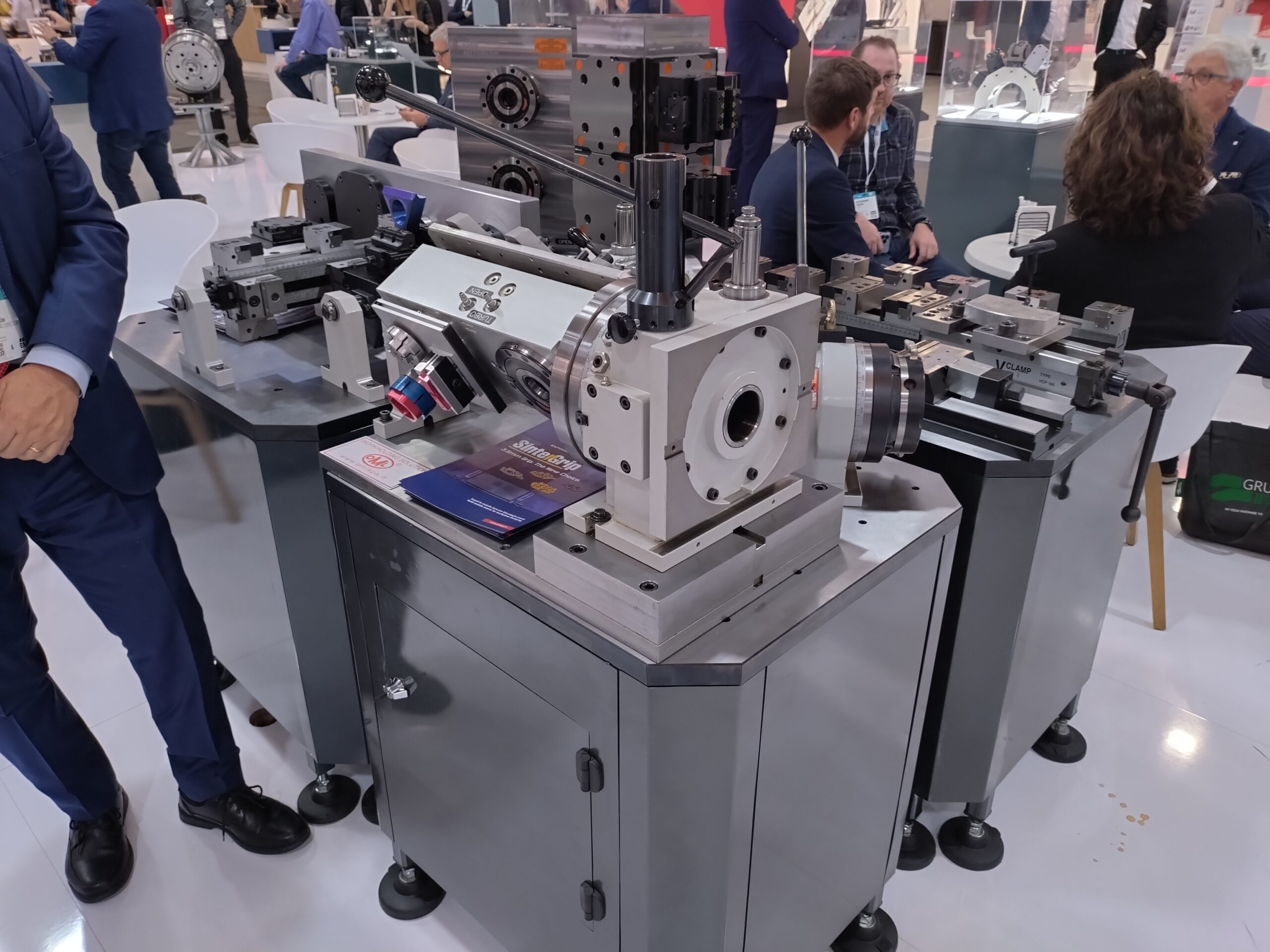

Our company’s products were also displayed at the booth of our Italian distributor.

Seeing this firsthand on-site made me feel very proud.

(I took some photos of the booth as well, so please take a look!)

This is our product called TOUCHDEX.

It’s built with a simple, non-electric mechanism, so it doesn’t require wiring or a power supply.

Born from the desire to create a tool that is simpler, more accurate, and more durable, TOUCHDEX includes only the essential functions, making it an easy-to-use machine.

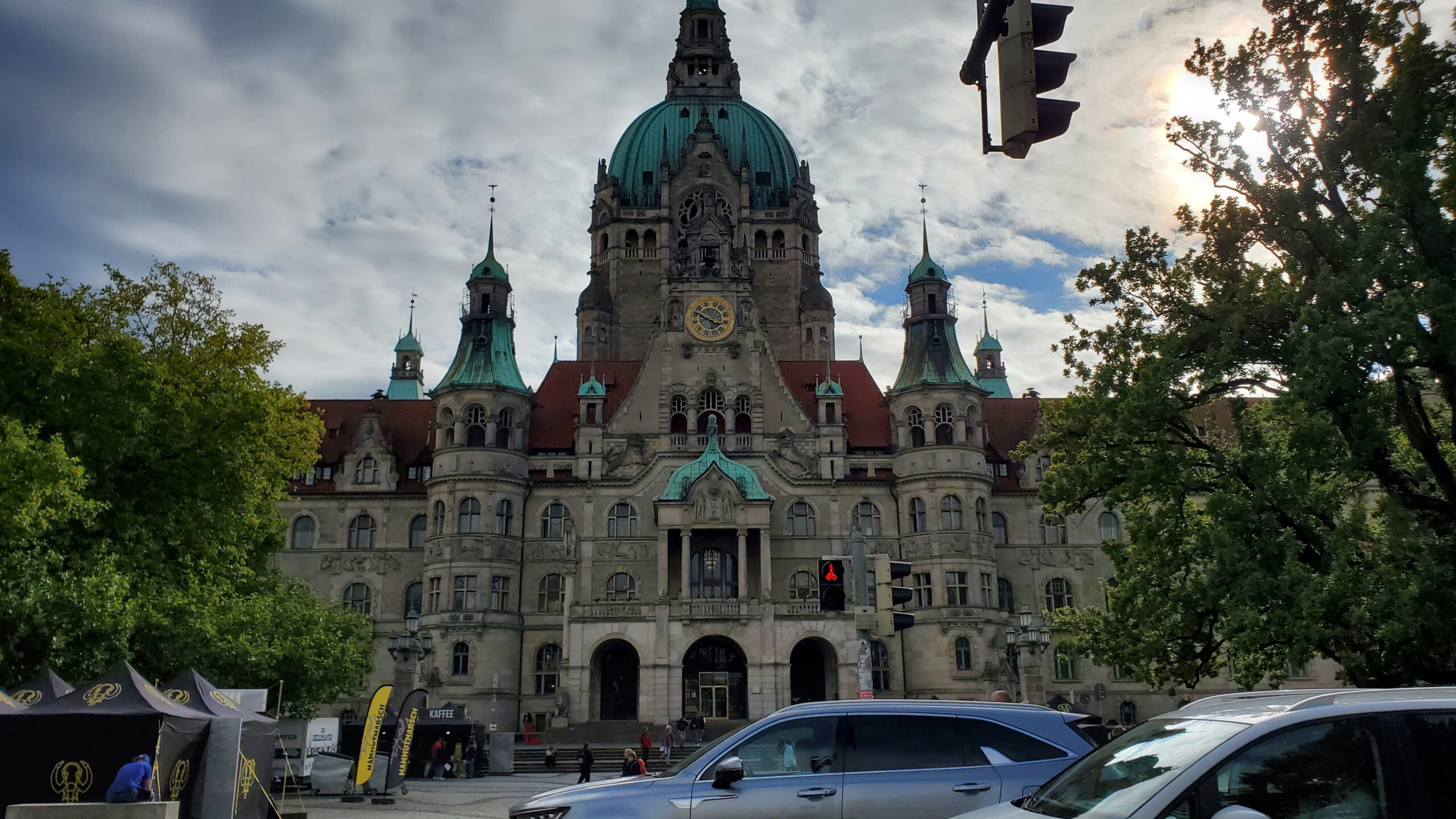

Amazing Hanover New City Hall: A Quick Visit During our trip

In the middle of a break, we had a little time to walk around Hanover city.

One of the places we stopped by was the Hanover New City Hall (Neues Rathaus).

The entire building looked just like a castle, and I couldn’t help but say “Wow…” at its impressive presence.

The interior was also richly detailed with stonework and design, giving it a very authentic European feel.

The architecture was so beautiful that every angle looked like a picture-perfect scene, and even though it was just a short break from work, I found myself captivated for a while.

Being able to see a style of building that’s rare in Japan up close gave me a valuable opportunity to feel the culture and history of Europe firsthand. ☺

Insights Gained from the Inspection and How We Plan to Apply Them

This visit to EMO was a truly valuable opportunity to experience a world I hadn’t known before.

Seeing firsthand how overseas manufacturers showcase and communicate their technologies really broadened my perspective!

At the venue, there were many demonstrations of robots automatically changing workpieces and jigs, and I was amazed by their efficiency and the overall sophistication of the systems.

Watching these automated processes in action made me realize just how advanced automation and software integration have become.

As I mostly explored the exhibition freely by myself, deciding my own route allowed me to engage with the displays more proactively, and on the last day, I had the chance to tour booths together with our president and the design section chief, which exposed me to viewpoints and ways of thinking I wouldn’t have noticed on my own.

I want to build on this experience and develop a broader perspective on manufacturing and technology trends, and gradually apply what I’ve learned to my daily work.